At Omnitek Warehouse Automation and Robotics, we know that picking operations are the heart of warehouse efficiency. Whether you’re focused on scaling your output, improving order accuracy, or reducing labor costs, the right picking strategy can unlock significant operational advantages.

We specialize in two core picking models: Goods to Person (GTP) and Person to Goods (PTG). Both are tailored to your needs, powered by leading-edge technologies, and delivered with a commitment to operational excellence.

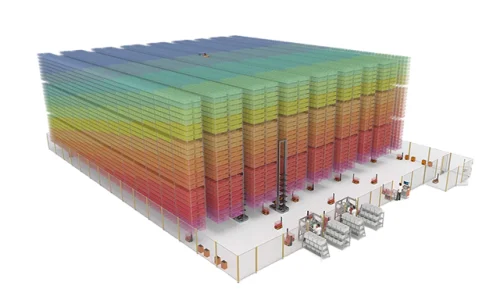

Our GTP solutions are modular, scalable, and adaptable. We integrate mobile robots, robotic shuttles, intelligent racking systems, and powerful warehouse management software (WMS) to create a seamless, highly efficient picking environment. Whether you require a starter setup with a few AMRs or a fully automated, large-scale picking operation, we design systems that grow with your business.

In addition to increasing pick rates, GTP systems drastically improve picking accuracy, often achieving error rates as low as 0.1%. This enhanced precision reduces costly order returns, improves customer satisfaction, and optimizes inventory accuracy. Furthermore, GTP automation dramatically reduces onboarding and training time for new warehouse staff — an increasingly critical advantage in today’s tight labor markets.

Another major benefit of GTP is space optimization. With robotic systems capable of accessing high-density storage and dynamic shelving configurations, warehouses can often reclaim 20–40% of floor space compared to traditional layouts.

When you work with Omnitek, you’re not just buying a system — you’re gaining a strategic partner. Our team conducts a detailed operational analysis to ensure the GTP solution we recommend is aligned with your KPIs, throughput targets, and budget. We also provide comprehensive support from design and planning through to installation, integration, and post-implementation optimization.

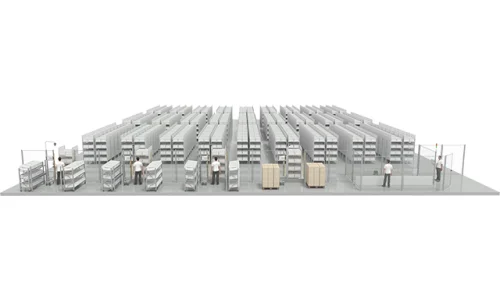

Person to Goods (PTG) remains a highly effective picking method for many warehouse environments. In PTG systems, operators travel to storage locations to retrieve products. Although traditional in nature, PTG can be optimized and modernized to deliver significant performance gains when correctly implemented.

At Omnitek, we offer a wide range of PTG solutions designed to suit different warehouse sizes, budgets, and operational complexities. From small-scale deployments utilizing smart picking carts and handheld devices, to larger-scale semi-automated solutions incorporating pick-by-voice, pick-by-vision, or robotic assistance, we build systems that match your operational goals.

Whether you are launching a single-robot pilot project or planning a multi-zone high-volume picking area, Omnitek can support you with technologies that are flexible, scalable, and future-proof. Our PTG solutions are ideal for warehouses seeking incremental automation without the upfront investment or complexity of full Goods to Person systems.

When designing a PTG picking system, we take into account warehouse size, SKU velocity, workforce configuration, and seasonal fluctuations to deliver the most practical, cost-effective outcome. Combined with training, best practice workflows, and optional smart technologies, our PTG solutions deliver measurable improvements in pick speed, accuracy, and labor efficiency.

We invite you to explore how we can support your automation journey, whether you’re just starting out or looking to elevate an existing setup. Let’s build the future of logistics—together.

At the intersection of logistics expertise and cutting-edge automation, we deliver intelligent solutions that transform warehouses into high-performance hubs.

Copyright © 2025 Omnitek Ltd. All Rights Reserved.

At the intersection of logistics expertise and cutting-edge automation, we deliver intelligent solutions that transform warehouses into high-performance hubs.

Saih Shuaib 2, Dubai Industrial City

+971 52 966 4299